Demonstration Advances to Produce Hydrogen Using Molten Salt Reactor Nuclear Technology

Terrestrial Energy USA, a fourth generation meltdown nuclear reactor development company, has partnered with Southern Co. and several national US Department of Energy (DOE) laboratories on a research and development (R&D) project based on the Finding a solution down is whether its reactor technology can efficiently generate hydrogen using nuclear heat and electricity.

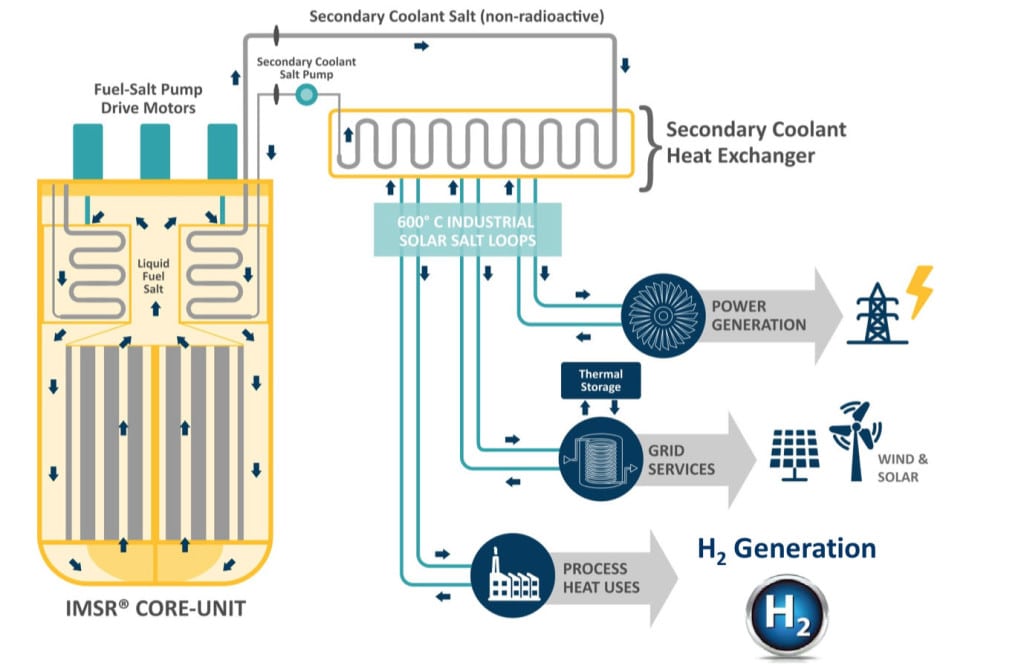

The two-year project will examine how efficiently and economically Terrestial’s IMSR (Integral Molten Salt Reactor) power plant can produce hydrogen on an industrial scale. It will test a hybrid sulfur process, which is a carbon-free method of producing hydrogen from water that “may be more efficient than high-temperature steam electrolysis,” Terrestrial said in a September 5 statement.

The main aim of the project is to “demonstrate the profitability of combining the hybrid sulfur process with an IMSR power plant for the large-scale production of hydrogen without greenhouse gas emissions on a commercial and industrial scale”.

The R&D demonstration follows two decades of research at the DOE’s Savannah River National Laboratory (SRNL). Sandia National Laboratories and Idaho National Laboratory will also collaborate on the project.

The breakthrough potential of hydrogen

The use of hydrogen as an energy carrier has recently received tremendous attention due to the element’s high flexibility. Hydrogen – the most abundant and lightest element – is odorless, non-toxic and has the highest energy content of any common fuel, meaning it can be used in a wide variety of applications, from power generation to transportation to industry.

However, it does not occur freely in nature and must be obtained (produced or “reformed”) from a separate energy source (such as electricity, heat or light). The majority of hydrogen today is generated with fossil energy, mainly through steam methane reforming of natural gas. Other widely used hydrogen producing processes include partial oxidation and autothermal reforming.

Several experts at the World Gas Conference in Washington, DC, in June this year, noted that hydrogen is increasingly being used – and possibly “groundbreaking” – for the storage of renewable electricity (converted by water electrolysis). In this process, hydrogen can be converted into energy and energy into hydrogen. Hydrogen could also replace fossil fuels in the chemical industry if bound carbon is combined with the element and used as a chemical feedstock. Some experts noted that hydrogen can also be used to electrify applications that currently use diesel and where batteries are not a viable solution, e.g. B. for heavy goods transport such as non-electrified trains or maritime transport. Others said hydrogen could also be used for decentralized power generation in a future energy system.

As Terrestial noted on Wednesday, the hydrogen market is projected to hit $ 200 billion by 2020.

The promise of molten salt reactors

Interest in molten salt reactor technology has also increased recently. Molten salt reactors being considered for future approval by the Office of New Reactors, a branch of the United States’ Nuclear Regulatory Commission (NRC), use either solid fuel or liquid fuel (fuel mixed with molten salt). The NRC notes that at least four molten salt reactors are under development – the 600 MWth LFTR (liquid fluoride thorium reactor) from Flibe Energy, the 557 MWth ThorCon from Martingale, the 1,250 MWth TAP (Transatomic Power) from Transatomic Power, and the 400 from Terrestial -MWth IMSR. “The thermal spectrum liquid fuel reactors use a fluoride salt and some use on-line removal of fission products and possibly actinides. Some have unique opportunities to add fissile and fertile material, ”said an April 2018 report from the Brookhaven National Laboratory’s Department of Nuclear Science and Technology.

Terrestial’s IMSR, a graphite moderated molten fluoride and salt reactor system with thermal spectrum, incorporates and refines many aspects of the molten salt reactor demonstrated by the Oak Ridge National Laboratory in the 1960s. According to the company, the small modular reactor “extends the applicability of nuclear energy beyond its current footprint on the grid-connected electricity markets” and also includes chemical synthesis and desalination. The technology, which is said to be launched in the 2020s, also promises to increase industrial competitiveness and energy security while driving deep decarbonization by reducing fossil fuel burning across a broad industrial front is displaced away.

According to the SRNL, the generation of hybrid hydrogen sulfide is a two-step thermochemical cycle based on the oxidation / reduction of sulfur. An important step in the reaction is the electrochemical splitting of water with a sulfur dioxide depolarized electrolyser. According to the SRNL, the demonstration could develop a “plausible way” to generate hydrogen gas with thermal and electrical energy (78% thermal energy and 22% electrical energy) at a price of less than USD 2 / kg hydrogen. Molten salt reactors are the “best choice” for high efficiency in power generation, it is said. In a presentation on June 13, 2018, SRNL stated that the total funding for the project to demonstrate the hybrid hydrogen sulfide production process integrated in a molten salt reactor would be split equally between the costs. The DOE’s share is $ 525,000 and the industry would pick up the remaining $ 525,000.

However, SRNL found that the main obstacles to the project are the balanced cost of hydrogen, the energy efficiency of the system and the total capital investment.

Integration of hydrogen generation in an integrated molten salt reactor IMSR. Courtesy Terrestial Energy

For Terrestial, the demonstration with a large utility company like Southern Co. will be crucial in bringing its technology to industrial markets. “Using an IMSR power plant to produce hydrogen more efficiently and economically is just one of many industrial uses for IMSR power plants beyond power generation,” said Simon Irish, CEO of Terrestrial Energy USA. “By removing carbon from hydrogen production, deep decarbonization is achieved. It shows the way to the production of climate-neutral fuels and emission-free fertilizers. “

In a statement on Wednesday, Noah Meeks, research engineer and project manager for the Southern Company, also praised the importance of the demonstration. “This is a potentially powerful project that combines the benefits of molten salt reactors with the development of an advanced water splitting process for generating hydrogen,” he said. “With a history of innovation, Southern Company looks forward to exploring this new technology with Terrestrial Energy USA.”

—Sonal Patel is a POWER Associate Editor (@sonalcpatel, @POWERmagazine).

Comments are closed.