Destroying PFAS in Sludge | WWD

Growing concerns about the contamination of water and soil with per- and polyfluoroalkyl substances (PFAS) have sparked interest in this emerging class of contaminants associated with sewage sludge. Two groups of PFAS are of particular concern to human health and environmental prospects, namely perfluoroalkyl sulfonates (PFOS) and perfluorooctanoate (PFOA), particularly in view of their persistent and bioaccumulative nature.

Due to the extensive use of PFAS compounds for over eight decades, including in everyday household items such as food packaging, cookware, stain resistant clothing, and industrial applications such as electroplating and fire fighting foam, it is widely believed that nearly all sewage sludge has some trace background level of PFAS compounds.

Are PFAS in land use biosolids?

Sewage sludges have been found to contain perfluoroalkyl carboxylates (PFCAs) and perfluoroalkanesulfonates (PFSAs), and additional compounds like GenX will be detected in liquids and solids as analytical methods improve. The fate and transport of PFAS compounds from biosolids to crops or soil is unknown. Some studies suggest that biosolids used to improve soil can lead to the transfer of PFAS to the soil, with PFAS available for uptake by plants and soil organisms.

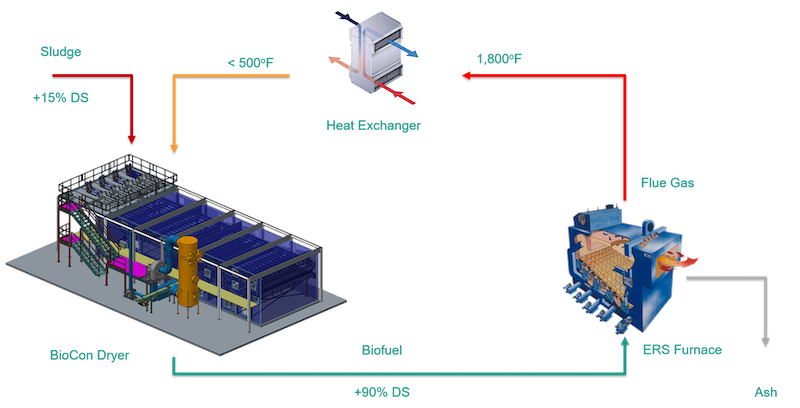

An example of a process flow diagram of a heat treatment process.

Many states require testing for PFAS in sludge prior to land use or are monitoring industrial pre-treatment programs to identify and eliminate the potential for PFAS entering sewage treatment plants that enter the environment. In Michigan alone, the Michigan Department of Environment has identified more than 11,000 sites contaminated with PFAS compounds, with more than 46 sites nationwide showing levels above the US EPA’s health recommendation limit of 70 parts per trillion, according to a report by the Detroit Free Press in groundwater.

While the concentrations of PFAS compounds in the sludge are relatively low, the need to identify a safe option for the final disposal of PFAS contaminated sludge is justified.

advertising

Traditional wastewater treatment methods in the USA

In the USA, sludge is traditionally stabilized under alkaline conditions and applied to the countryside. The alkaline stabilization process involves adding lime to sewage sludge and raising the pH to around 12 for no less than two hours of contact with numerous other operating methods to achieve varying degrees of treatment. The resulting sludge quality will vary, but in general the technique will only be able to remove fecal coliforms and salmonella, not egg cells from parasites or more complex compounds like PFAS.

Alternatively, sludge can be digested aerobically or anaerobically at different temperature ranges to successfully remove egg cells from parasites. However, any of these methods are not known to remove PFAS connections. These methods pose a potential threat to PFAS exposure as these compounds can exit these processes and be transported into the natural environment when biosolids – although they are stabilized to Class A or EQ quality – are landed or landfilled .

Thermal oxidation & PFAS destruction

Literature research suggests that thermal oxidation can be used to completely and permanently destroy PFAS from sludge. PFAS compounds such as PFOS break down when burned into easily washable and separated gases such as CO2, H2O and HF. In the early 2000s, previous studies showed that the degradation of PFOS occurs at temperatures above 600 ° C. However, this also led to the formation of strong greenhouse gases CF4 and C2F6.

Another related study showed that heat treatment of PFOS-contaminated sludge with the addition of Ca (OH) 2 reduced the emissions of CF4 and C2F6 in favor of CF3H and the formation of solid CaF2 and Ca5 (PO4) 3F.

A subsequent study found that the incineration of PFAS does not result in PFOS by-products. This is important when incineration is used to treat PFAS laden sludge. Current research shows that combustion processes can be adjusted at higher temperatures to mitigate these issues and adequately address the challenge of developing emission standards.

Combination of thermal drying and thermal oxidation processes

With thermal oxidation as the leading contender for the destruction of PFAS compounds in the sludge, the focus of this research has been on established technologies that can easily be used to meet market demands. Veolia Water Technologies has developed and successfully installed a safe and sustainable drying and incineration system in the market for municipal wastewater management with a system called BioCon ERS.

This system combines the efficiency of a convection air medium temperature belt dryer with a biomass oven. The aim is to burn off all of the organic material completely and to regain sensible heat. The heat available in the exhaust gas is collected in the belt dryer for use as process heat. This integrated dryer and energy recovery system is backed by heat generated when burning biosolids to drive the drying process, and the dried material powers the incineration system, making it a fully energetic and sustainable system.

While using BioCon ERS to destroy PFAS is new, the concept of combining these two technologies is not. For example, the City of Buffalo, Minnesota, has used biosolids as a fuel source in the Buffalo Wastewater Treatment Facility (WWTF) using this method since 2008. The solids treatment system in the Buffalo WWTF consists of both BioCon thermal drying and ERS thermal oxidation processes to reduce the amount of material that leaves the site while at the same time minimizing the total consumption of fossil fuels.

The heat treatment process consists of several steps as shown in the process flow diagram above. Dewatered solids are pumped from a storage silo through oscillating deposits into the dryer cabinet and onto a slowly moving belt in the dryer. The heat is transferred to the solids through air circulation between an air-to-air heat exchanger, which recovers energy from the furnace exhaust gas and the dryer cabinet. Moisture is removed from the drying air by continuously removing some of the air from the dryer, passing it through a condenser and returning it to the dryer.

Some of the air from the condenser is removed from the system in order to maintain a negative pressure on the drying system. The dirty air is mixed with fresh air and used as combustion air in the burners and oven to eliminate the need for separate odor control systems.

Knowing the flexibility this combined system offers, research has focused on determining the effectiveness of treating PFAS laden sludge with this system, which has been used successfully for more than a decade.

A detailed flow diagram of thermal drying and thermal oxidation.

A detailed flow diagram of thermal drying and thermal oxidation.

Oxidative study on a laboratory scale

A laboratory-scale oxidative study was carried out under the direction of Veolia in collaboration with the University of Dayton Research Institute in Ohio. The aim was to study the fate and transport of PFAS in sludge undergoing complete incineration and its effects on solid residue, process fluids and air emissions.

The experimental set-up comprised a thermal reactor, which is a discontinuous once-through reactor system. This system has been configured to represent the gas phase behavior in a waste incinerator prior to air pollution control. This setup enables the study of combustion under various conditions, including adjustments in temperature, applied oxygen, and residence time to mimic controllable conditions within the ERS.

The study was carried out in two phases. In phase 1, the transport efficiency of the laboratory setup was determined to ensure that PFAS can be recorded for analytical confirmation. In Phase 2, PFAS-laden sludge was thermally oxidized to determine whether PFAS could decompose at certain temperatures that fully mimick an ERS biomass furnace.

The results from phase 1 suggest that the transport efficiency is over 80%. Results of the phase 2 study show that complete degradation of PFAS compounds is possible with optimal thermal oxidation.

Based on the results obtained and the decomposition rates calculated so far, PFAS destruction using the proposed treatment train is achievable and exceeds the treatment goals. An attempt to develop into a fluorine mass balance is underway. Due to the highly reactive nature of HF and the lower limit of quantification of the HF analysis, it is possible that a fluorine mass equilibrium leads to a poor result or is not achievable.

The results of this study will be used to industrialize a full thermal oxidizer solution for the treatment of PFAS laden sludge. Veolia continues studies aimed at fine-tuning the treatment regimen on an industrial scale and further optimizing the air pollution control system

Comments are closed.