Nuclear worker protection opens doors for Australian innovators in power plants in the US and around the world

The Hanul power plant in South Korea, which uses an Australian Technofast CamNut® system to not only increase operational reliability, but also to increase the availability of generation

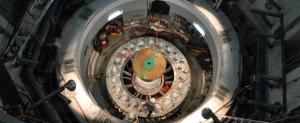

A circular series of CamNuts that allow power generation systems to be clamped and released at the same time

Typically, a tensioning tool will pull on the screw threads that protrude beyond the normal hex nut which is then screwed down to hold the loads created by the hydraulic operation of the tool. Without an available thread, the CamNut (in the picture) acts as a con

Technofast’s fast-acting CamNut® system with a quick-release fastener offers time savings and safety gains for the Korean fleet of nuclear power plants.

The time savings and safety gains demonstrated in these systems apply to all power generation applications, including nuclear, fossil, hydropower and green power generation. “

– John Bucknell

CRESTMEAD, QUEENSLAND, AUSTRALIA, November 25, 2021 /EINPresswire.com/ – The availability of power generation and safety in some of the largest nuclear power plants in the world is gaining international recognition for the fast acting CamNut® quick release system from Australian precision engineering company Technofast.

The successful use of the system in the Hanul nuclear power plant in South Korea – with an installed capacity of 6157 MW in two stages – was supplemented by its use in the country’s Wolsong, Shin Wolsong and Hanbit nuclear power plants as well as in large steam turbine plants.

On-going work within the Korean fleet of nuclear power plants, which provide a third of ROK’s electricity needs, has earned Technofast accreditation as a supplier to the country’s nuclear industry as it has received certification to design and manufacture equipment for that sector.

“Certification from a world leader in nuclear power generation opens the door to global applications for CamNut and complementary EziTite® systems in nuclear and power plants of all kinds,” says Technofast founder and CEO, Mr. John Bucknell.

“The time savings and safety gains demonstrated by these systems apply to all power generation applications, including nuclear, fossil, hydropower and green power generation. They provide the same benefits for any industrial application where workers need to ensure equipment uptime while dealing with hazardous situations such as radiation, heat, fuel, pressure and the need to work in confined work areas where unwieldy, time-consuming fastening tools are not recommended , have to avoid. “

Technofast’s hydraulic CamNut system and supplementary EziTite hydraulic screws and specialized supplementary products enable entire groups of fasteners to be tightened or loosened immediately and at the same time, instead of having to be laboriously assembled and loosened individually. An added benefit of CamNuts® is that they can be used where the thread length above the nut is insufficient to fit normal bolt tensioners, meaning users no longer need to replace expensive bolts to take advantage of direct hydraulic tensioning . The unique stepped washer provides a firm reaction point for tensioning without changing the countersink diameters on turbine housings. In addition, screws are not subject to any thermally induced loads due to rapid and uneven heating, which is important for longevity, reliability and safety.

The shutdown, maintenance, and installation of equipment for regular service operations is typically reduced by 60-80 percent, which cuts the maintenance schedules of Korean power plant applications by days, Bucknell says.

“This means big wins for every hour early that equipment can be brought back online to generate revenue. Days can mean millions of dollars in the manufacturing industry – and the CamNut and EziTite systems provide better risk management by getting people in and out of machines faster, which is big in industries like oil and gas, mining and energy, manufacturing and processing Plus is. ”

The savings on the original Korean nuclear and fossil power applications have been proven for more than a decade, and several new applications have followed their success. The CamNut system and its complementary products are used in key areas of Korean nuclear power generators, including:

• Combined post-heating valve (CRV) (CamNut – 1.75 inch)

• Main shut-off valve (MSV) (CamNut 2.5 inch)

• Control valve (CV) (CamNut 3in)

• High pressure control valve and shut-off valve (CamNut)

• Venturi (EziTite hydraulic nut 3 inch)

CamNuts are quickly installed by placing them on stud bolts and then hydraulically actuating them, stretching the screw to the precise required tension and then locking it mechanically with a locking device. The reverse procedure enables just as quick dismantling if it is required, for example, for annual or spontaneous maintenance.

The quick and safe hydraulic fastening system uses hydraulic power to pull and loosen the bolt rather than individually locking or loosening each fastener by operating personnel with wrenches to tighten the screw by turning the thread or by heat processes.

The direct extension methods of CamNuts avoid thermal loads and heat damage to the screws. Applied to existing fasteners, the CamNuts work at the same time to reduce downtime and extend the life of metal that is no longer exposed to thermal loads from rapid, uneven heating.

In addition to eliminating safety risks associated with more laborious maintenance methods, CamNut and EziTite fasteners optimize long-term safety by ensuring even tension across a series of bolts where clamping precision is critical to long-term performance. Extremely precise and even loads on the flange / connection increase the long-term reliability of the machines in use.

Benefits of Using Direct Clamping CamNuts:

• Versions for extreme situations / adverse conditions.

• Increased safety, quick assembly and disassembly.

• Requires little physical exertion, easy to use.

• Minimizes costs.

• Reduces downtime, optimizes profitable uptime.

• Enables the advantages of hydraulic clamping without changing expensive screws

• Increase the accuracy of the screw loading

• Eliminate the seizing of the thread

• Increase the service life of the hardware

• No hardware modifications

• The modular design reduces the overall weight of the tool.

• Achievable, reliable and precise clamping the first time.

• Reduce failures and damage.

• Eliminates the risk of shock and crush injuries caused by other tightening methods.

John Bucknell

Technofast

+61738036550 extension

[email protected]

Visit us on social media:

LinkedIn

Technofast CamNut solution

![]()

You just read:

News provided by

November 25, 2021 at 8:00 GMT

EIN Presswire’s priority is source transparency. We don’t allow opaque clients, and our editors try to carefully weed out false and misleading content. If, as a user, you notice something that we have overlooked, please make us aware of it. Your help is welcome. ONE Presswire, Everyone’s Internet News Presswire ™, seeks to define some of the boundaries that are appropriate in the world today. Please see our editorial guidelines for more information.

Submit your press release

Comments are closed.