Temperature resistant material for use in nuclear power plant doors

The safety of nuclear power plants is of paramount importance to the nuclear energy sector. An essential element of nuclear power plants are the robust protective doors that are installed in critical areas. A study published in Frontiers in Energy Research presented research on new temperature-resistant materials for these critical power plant infrastructure elements.

Investigation of a high temperature resistant shielding material for the shielding doors of nuclear power plants. Image source: Parilov / Shutterstock.com

The importance of nuclear shielding

The potential of radiation to cause death was discovered early in the atomic age. This discovery created an urgent need to create effective shielding materials and infrastructures for nuclear power plants to ensure the safety of workers and the environment, as well as to protect vital equipment outside of the shielded area.

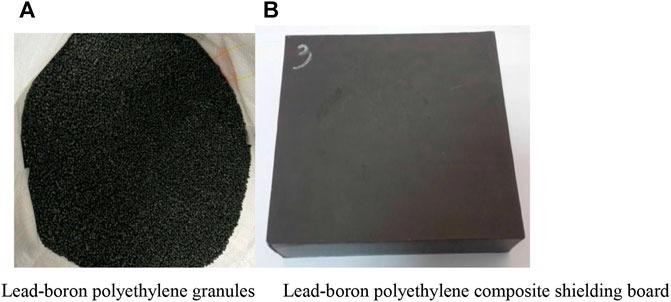

Samples of the lead-boron-polyethylene shield composite. Image source: Xiao-ling, L et al., Frontiers in Energy Research

Nuclear power plant elements that require shielding include reactors, pressure valves, and main circuit systems. Common materials used to shield doors include boron steel, epoxy, and lead-boron polyethylene. Since shield doors are located near radioactive areas, they must be constructed to withstand elevated temperatures, humidity and radiation.

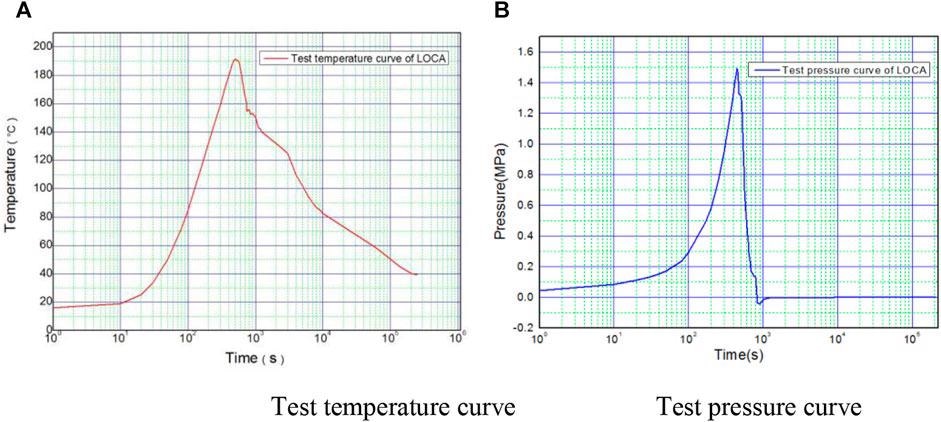

For this reason, shielding materials must not only have excellent mechanical properties, performance and aging resistance due to radiation and hydrothermal pressure over their recommended service life of 20 years. They must also withstand extreme temperatures of up to 190 ° C in the event of a Loss of Coolant Accident (LOCA).

Shielding doors and materials are subjected to intensive 48-hour LOCA simulations before they are approved for installation in nuclear power plants. Shielding doors must remain intact after this time and must not show any significant deformation. They must also be easy to repair and replace, and all performance counters must be within acceptable ranges.

Combination of materials in shielding doors

The optimal design of a shield door for nuclear power plants combines different materials for protection against neutrons and gamma radiation. Materials like lead absorb and scatter gamma rays through effects like the Compton effect and the photoelectric effect, and slow down fast neutrons through inelastic scattering. High carbon polyethylene can further moderate intermediate neutrons by elastic scattering, which are then absorbed by 10B boron carbide.

Environmental condition test parameters of the simulated design accident. Image source: Xiao-ling, L et al., Frontiers in Energy Research

However, polyethylene-based shielding materials have lower melting temperatures and heat distortion temperatures, which means that they cannot withstand the elevated temperatures caused by a loss of coolant accident. This leads to mechanical deformations of the materials such as softening and splashing, which affects the shielding effect and increases the risk of radiation leaks.

Even when equipped with protective elements such as lead or steel plates, temperatures on the surface of polyethylene-based materials can still exceed safe levels.

Improvement of the materials used in radiation protection

In order to investigate how the heat resistance and mechanical properties of radiation protection doors can be improved, a shielding material made of leaded polyethylene made of composite material was presented in the study published in Frontiers in Energy Research. This material would perform better during the intense heat of a leaked coolant accident scenario and prevent radiation leaks, thereby improving the level of safety for nuclear power plants.

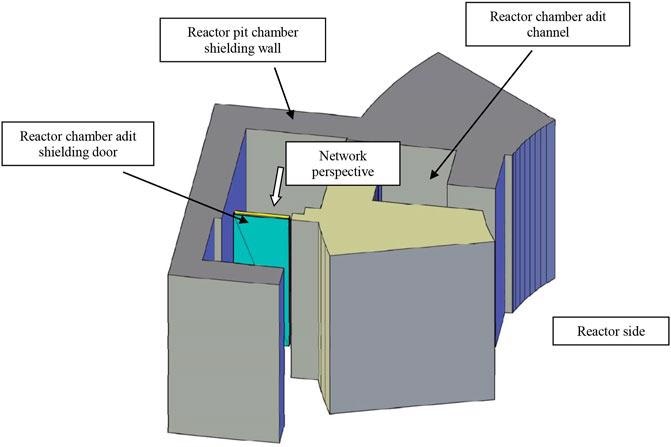

The modification of the raw material and the optimization of the compositional design further improved the properties and the performance of the composite shielding material presented in the research. The door design has undergone rigorous, extensive performance and sample testing. The shielding design was evaluated in the Hualong One reactor chamber tunnel under both normal and accident conditions.

The composition ratio of the shielding material was designed according to the Monte Carlo method and the genetic algorithm. Ultra high molecular weight polyethylene with block and graft copolymerizations was used throughout the blending process. As a result, the resistance of the material to elevated temperatures was improved and the maximum shielding effect achieved.

MCNP calculation simplified model for the shielding door of the reactor pit. Image source: Xiao-ling, L et al., Frontiers in Energy Research

Maleic anhydride was chosen as the modification molecule. This modification molecule optimized the uniformity and mechanical properties of elements such as lead and boron carbide mixed with polyethylene. Extensive environmental tests have been conducted on factors such as the composite’s neutron shielding properties, its mechanical performance, its resistance to hydrothermal and radiation-induced aging, and its performance in the event of a LOCA.

The results of the intensive material tests showed an all-round superior performance. The shield integrity was maintained even in the harsh atmospheric temperatures of a loss of coolant accident. It was further demonstrated3d that adding a 60 mm thick layer of this novel material to the shield door of the reactor tunnel reduced the gamma radiation dose by five times and the neutron concentration by ten times. This was within the zone requirements for the shield door.

The future

Research showed a composite shielding material that demonstrated superior performance even under catastrophic accident conditions. A widespread use of the material would drastically improve the safety of the staff and protect sensitive equipment from damage caused by radiation exposure.

further reading

Xiao-ling, L, et al. (2021) Study of a high temperature resistant shielding material for shielding doors of nuclear power plants [online] Front. Energy res. | frontiersin.org. Available from: https://www.frontiersin.org/articles/10.3389/fenrg.2021.751654/full#h1

Disclaimer: The views expressed here are those of the author in his private capacity and do not necessarily reflect the views of AZoM.com Limited T / A AZoNetwork, the owner and operator of this website. This disclaimer is part of the terms of use for this website.

Comments are closed.