Thorium power has a protactinium problem

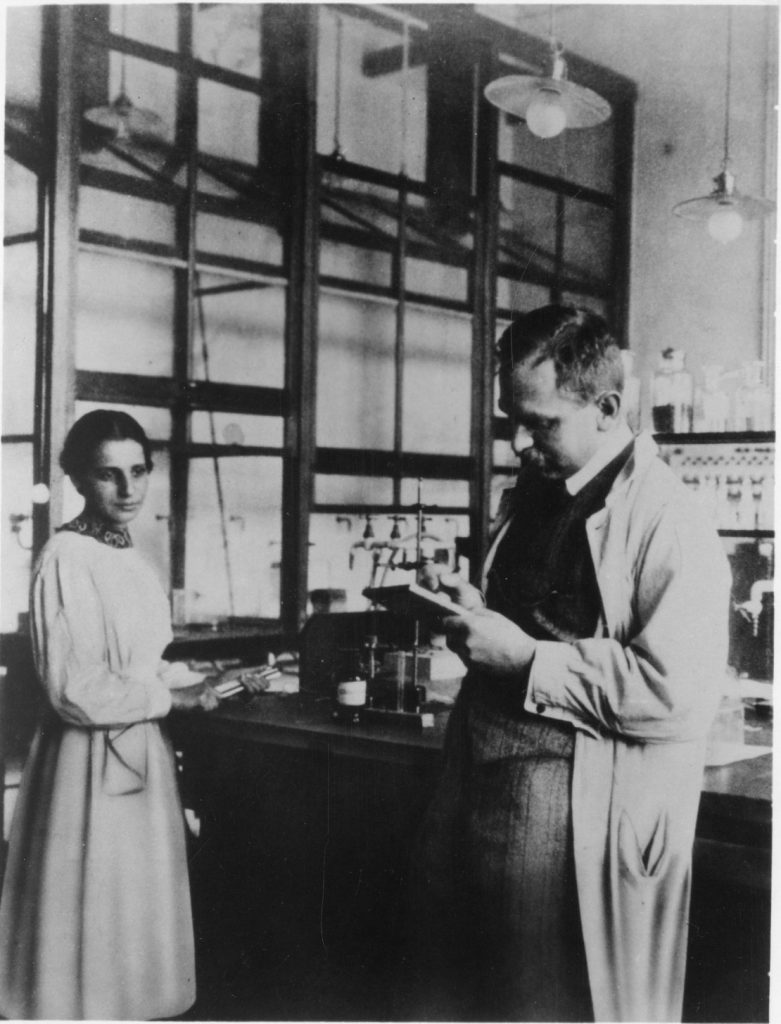

Physicist Lise Meitner and radio chemist Otto Hahn in their German laboratory in 1913, around the time Meitner began the experiments that led to the discovery of protactinium. Photo credit: Smithsonian Institution Archives, image number SIA2008-3209

In 1980 the International Atomic Energy Agency (IAEA) observed that protactinium, a chemical element produced in thorium reactors, could be separated and decomposed into isotopically pure uranium 233 – a suitable material for the manufacture of nuclear weapons. The IAEA report, entitled “Advanced Fuel Cycle and Reactor Concepts” concluded that the proliferation persistence of thorium fuel cycles “equals” the uranium / plutonium fuel cycles of conventional civil nuclear reactors, provided that both contain them Reprocessing of spent fuel assemblies to isolate fissure material.

Decades later, history changed. “Th[orium]Fuel-based fuels and fuel-cycle fuels have intrinsic persistence to proliferation, ”the IAEA said in 2005. The mainstream media have since repeated this view many times without qualification. Several scientists have recognized the inherent risk of proliferation of protactinium separations in the thorium fuel cycle, but the perception that thorium reactors cannot be used to make weapons remains. As technology has advanced, the basic radiochemistry that governs nuclear fuel reprocessing remains unchanged. Hence, this change of perspective is puzzling and reflects a failure to understand the importance of protactinium radiochemistry in thorium fuel cycles.

Protactinium is 100 years old. The importance of protactinium chemistry for the extraction of highly attractive fissile material from thorium has been recognized since the 1940s. However, the story really begins 100 years ago during the earliest research on natural radioactivity. In 1918 the Austrian-Swedish physicist Lise Meitner and the German chemist Otto Hahn wanted to discover the long-lived isotope “Eka-Tantalum”, which is said to be between thorium and uranium in the periodic table. The isotope they were looking for decayed to actinium, which has always been found with uranium, but which was known to be the parent of an unknown natural radioactive decay chain that differs from that of uranium 238, the most abundant isotope of uranium found in nature .

Meitner and Hahn discovered that treating pitchblende with nitric acid yielded an insoluble fraction of silicon dioxide associated with tantalum and eka-tantalum. After many years they purified enough eka-tantalum for identification and measured its properties. As the discoverers of the longest-lived isotope of eka-tantalum, Meitner and Hahn named this new element protactinium. They had isolated Protactinium 231, a member of the uranium 235 decay chain. In 1938 they discovered that Protactinium 233 could be made by neutron irradiation of thorium 232, the most abundant isotope in naturally occurring thorium.

For the next few decades, Protactinium was surrounded by “mysteries and witchcraft” due to its natural scarcity and confusing chemical properties. We now know that Protactinium’s peculiar chemistry is due to its position in the periodic table, which gives the element very different chemical properties than its neighbors. Protactinium behaves as differently as thorium and uranium that under many conditions a separation is inevitable.

The scientists first investigated the macroscopic chemistry of Protactinium in the Manhattan Project. In 1942, Glenn T. Seaborg, John W. Gofman, and RW Stoughton discovered uranium 233 and observed its tendency to fission. Compared to naturally occurring uranium 235, uranium 233 has a lower critical mass, which means that less material can be used to build a weapon. And compared to weapons grade plutonium 239, uranium 233 has a much lower rate of spontaneous fission, allowing for simpler weapons that are easier to construct. A 1951 report by the Engineering Department of the Manhattan Project describes extensive efforts to produce uranium 233 by neutron irradiation of thorium 232. Since the original thorium feedstock was often contaminated with natural uranium 238, scientists obtained one grade of pure uranium 233 of methods for the separation of the intermediate protactinium 233.

At this point, advances in technology and uranium shortage predictions sparked interest in developing a breeder reactor that would produce more fissile material than it consumed. In the late 1960s, a team at Oak Ridge National Laboratory designed a molten salt breeder reactor that ran on thorium and uranium dissolved in fluoride salts. However, it could only grow uranium 233 by continuously removing contaminants – including protactinium 233 – from the reactor core. In order to improve the breeding conditions, the researchers investigated methods of removing protactinium from the molten fluoride salts.

In 1977, President Jimmy Carter banned the commercial reprocessing of spent fuel, citing concerns about the proliferation of technologies that could be used to manufacture nuclear weapons. And given the high start-up costs for developing new reactors, the molten salt breeder would not be found on the energy market. With the end of research on thorium reactors, the ambitious research on protactinium separations ended. Over time, the role of Protactinium in extracting weapons-grade uranium 233 from thorium has been largely forgotten or rejected by the thorium community.

Reborn Thorium Reactors. Fast forward to 2018. Several nations have studied thorium power for their nuclear power portfolios. India is one of the most important. India is plagued by perennial uranium shortages, but has abundant thorium resources and is highly motivated to develop thorium reactors that can grow uranium 233. India now operates the only uranium 233 fueled reactor, the Kalpakkam Mini-Reactor (better known as KAMINI).

Thorium reactors have other potential advantages. They could produce less long-lived radioactive isotopes than traditional nuclear reactors, making it easier to dispose of nuclear waste. Molten salt reactors offer potential improvements in reactor safety. In addition, there is a persistent perception that thorium reactors are inherently resistant to proliferation.

The uranium 233 produced in thorium reactors is contaminated with uranium 232, which is produced via various neutron absorption pathways. Uranium 232 has a half-life of 68.9 years and its daughter radionuclides emit intense, highly penetrating gamma rays that make the material difficult to handle. A person standing 0.5 meters from 5 kilograms of uranium 233 and containing 500 ppm uranium 232 a year after it was separated from the daughters of uranium 232 would receive a dose that would meet the annual legal limits for radiologists in less than exceeds an hour. Therefore, uranium 233 produced in thorium reactors is “self-protected” as long as uranium 232 levels are high enough. However, the extent to which uranium 232 provides adequate protection against diversion of uranium 233 is controversial. Uranium 232 does not impair the favorable fissile material properties of uranium 233, which is classified as “highly attractive” even in the presence of high uranium contents. Uranium 233 becomes even more attractive if uranium 232 can be reduced or eliminated entirely. This is where the chemistry of protactinium becomes important.

Protactinium in the thorium fuel cycle. When irradiated with thorium 232, three prototinium isotopes are formed. Protactinium 231, 232 and 233 are produced by either thermal or rapid neutron absorption reactions with various thorium, protactinium and uranium isotopes. Protactinium 231, 232, and 233 are intermediates in the reactions that ultimately form uranium 232 and uranium 233. Protactinium 232 decays to uranium 232 with a half-life of 1.3 days.Protactinium 233 decays to uranium 233 with a half-life of 27 days.Protactinium 231 is a special case: It does not decay directly into uranium, but can absorb a neutron in the presence of neutrons and become Protactinium 232.

Neutron absorption reactions only occur in the presence of a neutron flux within or immediately around the reactor core. Radioactive decay occurs whether or not neutrons are present. With irradiated thorium, the real problem is separating protactinium from uranium, which may already contain significant amounts of uranium-232. The production of Protactinium 232 will cease as soon as Protactinium is removed from the neutron flux, but Protactinium 232 and 233 continue to decay to uranium 232 and 233, respectively.

The half-lives of the protactinium isotopes have a positive effect on potential proliferators. Since Protactinium 232 disintegrates faster than Protactinium 233, the isotopic purity of Protactinium 233 increases over time. If it is separated from its uranium decay products a second time, this protactinium decays into equally pure uranium 233 in the next few months.Taking careful consideration of the relevant radiochemistry, the separation of protactinium from uranium in spent thorium fuel can produce uranium 233 with very low uranium concentrations 232 – a product suitable for the manufacture of nuclear weapons.

Scenarios for diffusion. Although thorium is commonly associated with molten salt reactors, it can be used in any reactor. Different types of fuel circuits allow a practical and quick reprocessing for the extraction of Protactinium. One of these is the aqueous reprocessing of thorium oxide “blankets” that are irradiated outside the core of a heavy water reactor. Many heavy water reactors have on-power refueling, which means that irradiated thorium can be removed quickly and frequently without shutting down the reactor. Since very little fission would occur in the ceiling material, its radioactivity would be less than that of spent fuel from the core and it could be reprocessed immediately.

There are innumerable possibilities for the aqueous separation of protactinium from thorium and uranium oxides, including the widely proposed thorium-uranium extraction process (THOREX). Alternatively, once dissolved in acid, protactinium can simply be adsorbed onto beads of glass or silica using the same chemical mechanism that Meitner and Hahn used a century ago to isolate protactinium from natural uranium.

Another scenario is the continuous reprocessing of molten salt to remove protactinium and uranium from thorium. Oak Ridge researchers investigated the feasibility of online protactinium removal as part of the Molten Salt Breeder Reactor program. In a second step, uranium can then be separated from the protactinium.

Sensible protective measures. Protactinium separations provide a route to the recovery of highly attractive weapon grade uranium 233 from thorium fuel cycles. The difficulties in ensuring commercial spent fuel reprocessing are significant for any type of fuel cycle, and thorium is no exception. Reprocessing creates unique protection challenges, particularly in India, which is not a member of the Nuclear Non-Proliferation Treaty.

There is little to be gained from calling thorium fuel cycles intrinsically proliferation resistant. The best way to realize nuclear power from thorium fuel cycles is to acknowledge its unique vulnerabilities to proliferation and adequately protect it from theft and misuse.

Comments are closed.